When we have lots of continuous duty tasks then two-stage air compressors are often preferable over a single-stage air compressor. Because 2-Stage compressors are more powerful and can perform better in tough situations.

So in this article, we are going to discuss what is a 2-stage compressor? How do a two-stage air compressor work and their advantages and disadvantages?

So without any further delay let’s get straight into the article.

Table of Contents

Types of Compressor According to the Stages

Before going to 2 stage compressor you need to know about all types of air compressors depending on the stages.

- One-stage air compressor:- It compresses the air on one stage only so it can deliver lower PSI. That’s why it is good for light-duty tasks.

- Two-Stage compressor:- It can compress the air in two stages and because of that, it can provide more PSI than a 1-stage compressor. Good for medium to heavy-duty tasks.

- Multistage compressor:- It can compress the air in three or more stages to get the maximum PSI, And these are used for continuous heavy-duty operations.

What is 2-stage Air Compressor?

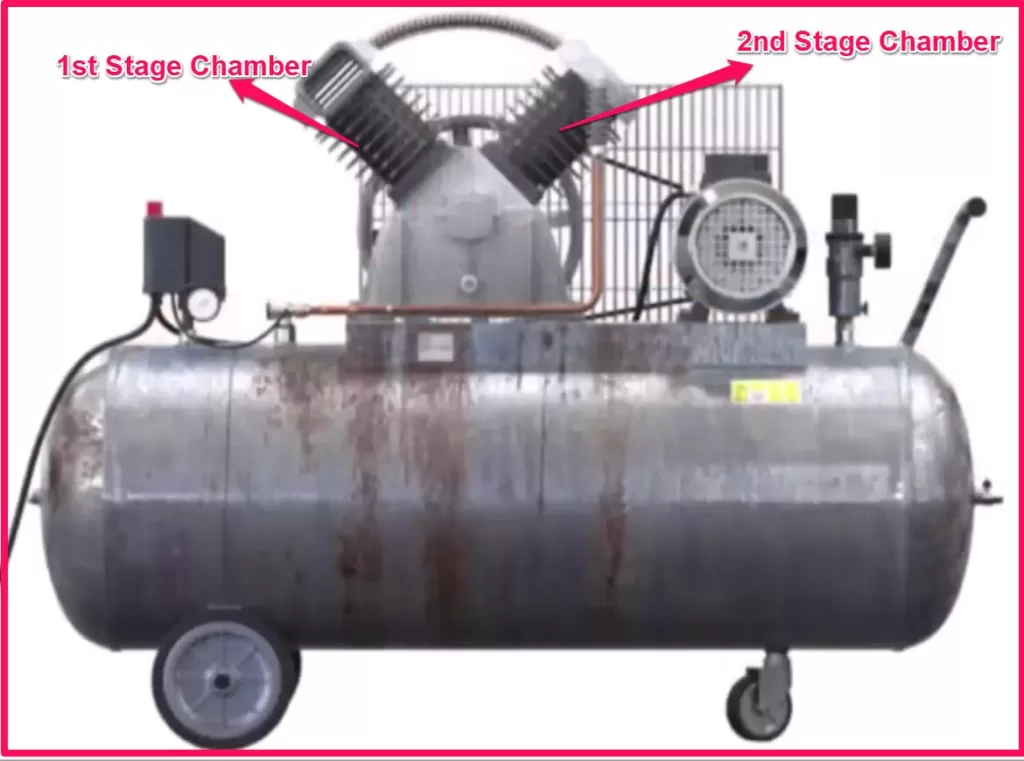

As I told you earlier that two-stage compressors are those compressors that compress the air in two stages. So the air gets compressed twice to get the higher PSI.

Generally, a two-stage air compressor is equipped with a twin-cylinder named a Low-pressure cylinder and a High-pressure cylinder and the volume of a Low-pressure cylinder is greater than a high-pressure cylinder.

Basically, Two-stage air compressors are used to get the higher air pressure on an estimated 2-stage compressor that can deliver 175 to 200 PSI of air pressure. But the single-stage pressure can provide only 70 to 90 PSI of air pressure.

So that is why 2-stage compressors are way more efficient when it comes to heavy-duty operations like running heavy-duty air tools and for most of the automotive tasks.

Read More: What Kind of Oil Goes in a Central Pneumatic Air Compressor

Read More: How to Quiet an Oilless Air Compressor

Read More: How to Increase CFM on Air Compressors

Main Components of Two-Stage air compressor

Before discussing the working principle of a 2-stage compressor we need to know about the components used for the two-stage compressor.

- Inlet Valve

- Outlet Valve

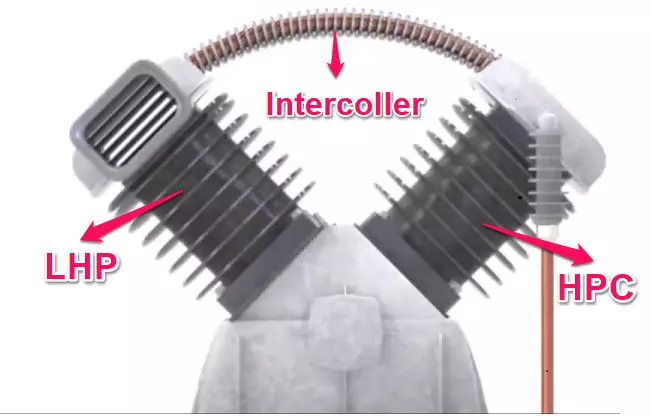

- Low-Pressure Cylinder(LPC)

- Intercooler

- High-Pressure Cylinder(HCP)

Inlet Valve:- It is a valve that is present on the piston cylinder. Which is actually used to take the air inside the cylinder.

Outlet Valve:- It is also present inside the cylinder but this valve is used to take it out of the cylinder after the compression process.

Low-Pressure Cylinder(LPC):- In this cylinder, the air is compressed up to 90 PSI. And due to the low air pressure, this cylinder is named a low-pressure cylinder. And the dimension of this cylinder is higher.

Intercooler:- After the first stage of compression the air becomes too hot and that’s why a cooling pipe is placed between LPC and HPC which is known as an intercooler. And here the colling process is done by air or oil or water.

High-Pressure Cylinder(HPC):- In this cylinder, the cooled compressed air again sends for second-stage compression. And here the air is compressed up to 175PSI, that’s why this is called a high air pressure cylinder.

How does a two-stage compressor work

So after knowing about the components used in a 2-stage air compressor now we are going to discuss the working principle of a 2-stage air compressor. Basically, a two-stage compressor works on few steps:-

1.) First Stage Compression

So when we turn on the pump of an air compressor then the Low-Pressure Cylinder piston goes down and the inlet valve creates the suction of clean air into the cylinder. Once the suction process is done, the inlet valve closes and the piston begins to move upward to reduce the cylinder volume, which increases the pressure of air up to 75 PSI.

2.) Cooling

During the 1st stage of compression, the air got pressurized so the pressure and temperature of the cylinder increases and the volume decreases and because of the high pressure, the outlet valve opens and the hot pressurized air send to the intercooler to lower the air temperature before entering into the high-pressure cylinder(HPC).

3.) Second Stage Compression

Now the cool pressurized air sends to the high-pressure cylinder(HPC). Again the same compression process repeats. The inlet valve opens and the piston moves down and sucks the cold pressurized air into the high-pressure cylinder, and after the suction process is complete, the inlet valve closes and the piston moves up, Due to which the air pressure increases from 75 to 175 PSI. Finally, the high-pressure air accumulates on the air tank.

Note:- So the 2-stage air compressor can deliver up to 175 PSI of air pressure which is good to operate heavy-duty air tools.

Read More: Best Air Compressor Under 400 Dollars

Read More: Best Air Compressor Under 500 Dollars

Read More: Best Air Compressor Under 200 dollars

Read More: Best Air Compressor Under 300 Dollars

Advantages and Disadvantages of 2-Stage Air Compressor

So far we have learned what is a 2-stage air compressor and its working principle. But now we are going to discuss its advantages and disadvantages. Because if you are planning to buy a 2-stage air compressor then its also good to know about its advantages and disadvantages.

Advantages of 2-stage Air Compressor

Powerful Performer:- Two-stage air compressor can compressor air in 2 stages and can deliver up to 175 PSI of air pressure. So it can be used for heavy-duty operations. These are also preferable for industries too.

Both Electricity and Gas Powered Option Available:- Two-stage air compressor can be operated through gas as well as electricity. So you according to your convenience you can choose a 2-stage compressor.

Larger Tank Capacity:- Generally 2-stage air compressors are so powerful and they are also equipped with a large tank capacity. So you can easily use this compressor for continuous duty operations.

Highly Durable and Reliable:- Because 2-stage compressors come with a cooling system that cools the hot compressed air, it prolongs its lifespan and makes it more durable.

Good For Continuous Duty Operations:- These air compressors are so powerful that they can provide very high PSI and CFM so these are good for continuous duty operations.

Disadvantages of 2-Stage Air Compressors

Not a Portable Compressors:- Two-stage compressors are super powerful compressors equipped with large air tanks that make them heavy. So you need to fix those compressors in one place.

Expensive:- So obviously if you need a powerful air compressor you need to pay more and 2-stage compression makes them super powerful.

Required Higher Power:- These compressors are equipped with a 2-stage motor which required more energy as compared to a single stage. So the fuel consumption is also higher.

High Noise Level:- Generally 2 stage pumps generate higher horsepower which makes them noisier.

FAQs for Working Principle of 2-Stage Air Compressor

1. How does a 2 stage compressor work?

In short two-stage air compressor works in three stages.

1. 1 stage of compression up to 75PSI.

2. Then cool the compressor air through the intercooler.

3. 2 stages of compression up to 175 PSI.

2. What is the advantage of a two-stage compressor?

There are so many advantages of a 2-stage air compressor:-

1. More powerful than single-stage compressors.

2. Delivers higher PSI and CFM.

3. Good for heavy-duty operations.

4. Low moisture buildup.

5. Highly durable and reliable.

6. Large air tank also equipped with compressors.

3. When would a two-stage air compressor be used?

Because 2 stage compressors are one of the most powerful air compressors and can provide very High air pressure. So these compressors are good for continuous heavy-duty applications.

4. Is a 2 stage air compressor worth it?

It completely depends on you which types of task you want to do with an air compressor. So if you have heavy-duty air tools like Air Belt Sander, Die Grinder, Cut-Off Tool then only you should go with 2 stage air compressors. Because these compressors are more expensive and can provide higher air power.

5. Is a two-stage air compressor better than a single-stage?

The main difference between these compressors is the air pressure, 2-stage can provide more air pressure than a single-stage compressor. But 2 stage compressors are more expensive. So both types of the compressor are good but it depends on you that which type of air compressor you need.

Conclusion: What is a 2-Stage Air Compressor And Its Working Principle

We have included everything so that you can easily understand How does a two-stage compressor work.

If you have any doubt regarding this process then, let me know in the comment box. We will definitely help you with that.

So guys if you like our post then don’t forget to share this with your friends.

By the way thanks for visiting.